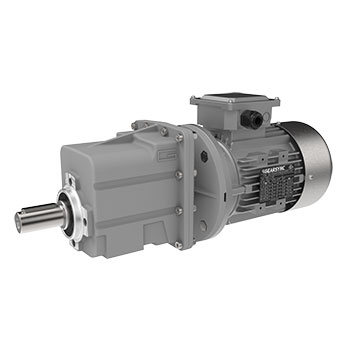

Gearsync – Helical Inline Gearmotors and Gearboxes

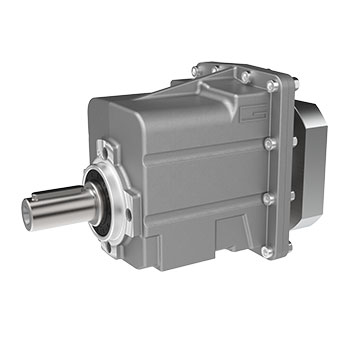

Discover DieQua’s modular Helical Inline gearbox series: the GI and GHI models, purpose-built for compact power transmission and system versatility. Engineered with an axial design to minimize installation footprint, these gearboxes are ideal for applications where space and alignment are critical.

The GI and GHI series offer a torque range from 70 Nm (52 ft-lbs) up to 3,500 Nm (2,582 ft-lbs) and are available in nine frame sizes, providing broad scalability for diverse motion control and industrial automation needs. Their modular design supports multiple input configurations—including Gearmotor, NEMA, IEC, and servo motor mounts—ensuring seamless compatibility with standard and high-performance drive systems.

The inline helical gearing provides efficient power transmission with low noise and high precision, making them suitable for continuous-duty applications. Built for durability and long service life, GearSync Helical Inline Reducers deliver the performance and integration flexibility demanded by today’s evolving machinery requirements.

- 9 sizes

- Input power capacities from 0.09kW-30kW

- Gear ratios: 3.7-398.3:1

- IP66 rated motor with class F insulated windings

- Feet options available

- Output flange option available

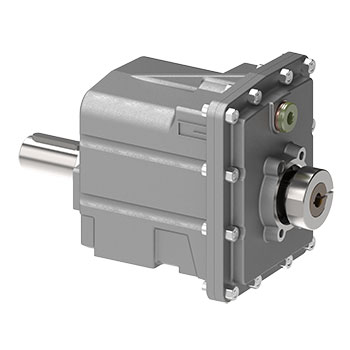

- Input shaft version available

- High modularity allows seamless integration into a variety of drive systems

- Compact axial design ideal for space-constrained installations

- Quick interchangeability of components reduces downtime during maintenance

- Designed for precise alignment between motor and driven machine

- Optimized thermal dissipation for improved performance under continuous operation

- Integrated motor adapters available for various motor types

- Lightweight construction enables easier handling and installation

- Optional accessories for enhanced control and customization

- Torque outputs from 70 Nm up to 3500 Nm

Coming Soon!

Gearsync Overview Flyer – PDF (922KB)

Compatibility Guide – PDF (3MB)

What’s Next?

Other Models Available

Why Choose a Gearsync Gearbox?

A major advantage of the Gearsync servo gear unit is its high efficiency, reduced backlash, and high torsional stiffness, ensuring precise positioning, misalignment compensation, and stability in dynamic applications such as robotics, automation, and packaging machining. Key features include seamless integration input and flexible coupling design advantages. The high degree of modularity is a design feature of GI and GHI helical in-line speed reducers and geared motors range. It is possible to set up the version required using flanges or feet. DieQua Corporation’s extensive knowledge of gear technology, in-house repair services (especially emergency breakdowns for quick turnaround), and ability to create custom solutions for optimal performance, further enhance the value of the Gearsync product line. As an ISO 9001-certified company, DieQua ensures that all products meet the highest quality and performance standards, providing customers with a single-source supplier for gearboxes, couplings, and gear motors.